In our last piece, we provided information on our gasket plate heat exchangers and the advantages they hold.

Our follow up piece now looks into how they work and how they are assembled.

The operating principle of the AEL Plate Heat Exchanger ensures that most fluids such as water can be instantaneously heated or cooled on demand to suit any application.

The water temperature leaving an AEL Plate Heat Exchanger can be easily maintained and controlled within 1 or 2 degrees Celsius at a constant preselected temperature.

Being instantaneous a Plate Heat Exchanger does not require storage so has very low standing heat losses and practically eliminates the possibility of dangerous bacteria growth such as legionella.

The AEL Plate Heat Exchanger plates are made from stainless steel with a corrugated profile which creates turbulence as the fluid flows through the unit which scrubs and helps to reduce any deposits forming on the

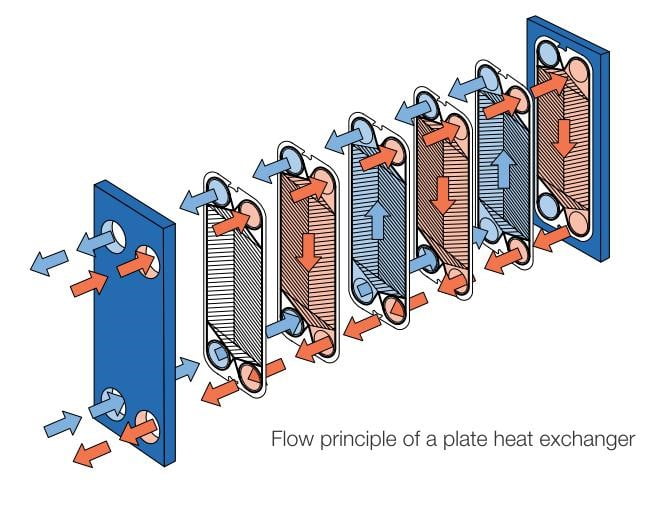

The arrangement of the plates, separated by a gasket, ensures that the primary and secondary fluids do not mix.

Additional plates can be added to increase a plate heat exchangers performance without having to disconnect the pipework from the unit.

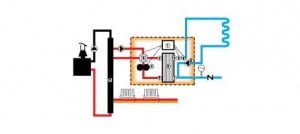

Typical Heating System

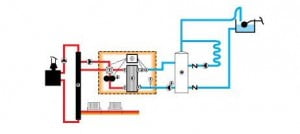

Typical DHW System

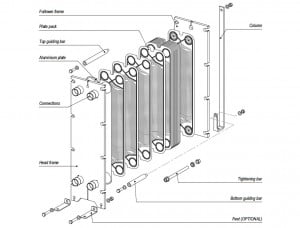

How is a Heat Plate Assembled

A plate heat exchanger has a frame with one fixed heavy front section with four ports and a heavy moveable section that slides along a carrying or guiding bar. There are a number of clamping bolts that run down the side of both heavy plates in which a varying number plates are placed and clamped together.

Each plate is supplied with a gasket, so that the plates form a closed system of flow channels, which will allow the primary and secondary fluids to flow through every second plate.

The gaskets are either clipped or glued onto the plates separating different medias on the Primary and secondary circuits.

Gaskets

The first and last plate in each heat exchanger are fitted with a gasket around all four ports and the intermediate plates will have a gasket around two ports controlling which plate circuit the fluid will be allowed to flow down.