Shell and tube heat exchangers are considered one of the most effective types of heat exchanger available in the UK.

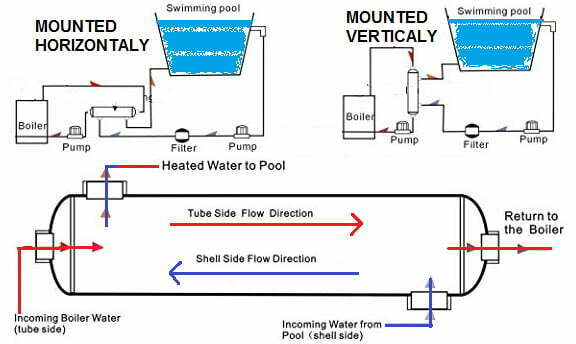

Basically a shell and tube heat exchanger has a cylindrical shell with a tube bundle in the center. The high thermally efficient tube bundle allows heat to be exchanged between the hot fluids flowing outside the tubes and the cooler fluid ( e.g pool water) flowing through the tubes.

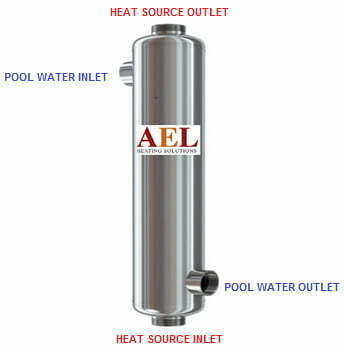

NOTE: LOCATION OF FLOW AND RETURN CONNECTIONS CAN VARY WITH EACH MODEL.

Shell and tube heat exchangers are usually used in applications that require cooling or heating large volume of process fluids with minimal pressure loss even though this can quite often still be achieved with a Plate Heat Exchanger.

There is a choice of different types of shell and tube heat exchanger designed to suit different applications in most industries.

The Construction of a Shell and Tube Heat Exchangers

The following four components are the main parts of a shell and tube heat exchanger:

1. Tube Bundle: A tube bundle that comprises of tube sheets and tubes.

2. Shell: The tube bundle is fitted inside the outer shell.

3. Return Header: is the part of the heat exchanger where the cooler return fluid enters the heat exchanger.

4. Return Header:is the part from where the hot or heated fluid flows from the heat exchanger.

Materials Used for Shell and Tube Heat Exchangers

Materials Used for Shell and Tube Heat Exchangers

- Cupronickel Alloys

- Titanium

- Carbon Steel

- Brass Alloys

- Stainless Steel

What Are the Benefits of Using Shell and Tube Heat Exchangers

AEL Shell and tube heat exchangers are popular in a number of industries because:

- They have more heat transfer efficiency than most other heat exchangers.

- They are perfect for corrosive applications such as swimming pool heating and salt water.

- They can be easily cleaned.

- They are compact in size.

- They can be banked to increase capacity /output.

- They give a great return on investment because they give long term efficient service and are affordable compared to other heat exchangers.

- Pressure testing is simple.

- They are perfect for systems that operate at high operating pressure and temperatures.